In this “Quick Tip” we show you how to properly and accurately drill a drop for the DLE 30, 35, or 40 CC engines.

You will need a few tools to do this:

- DLE 30CC propeller drill guide

- #22 Drill Bit

- Cordless drill (drill press would be better but a drill will work)

- Prop reamer to ream center of prop to 10mm

First start by reaming the center of the prop to 10mm. Insert the drill guide into the propeller to check fitment. I noticed my drill guide was very slightly undersized so I added one layer of electrical tape to take up any side to side slop. This will help insure the drill guide is perfectly centered on the propeller.

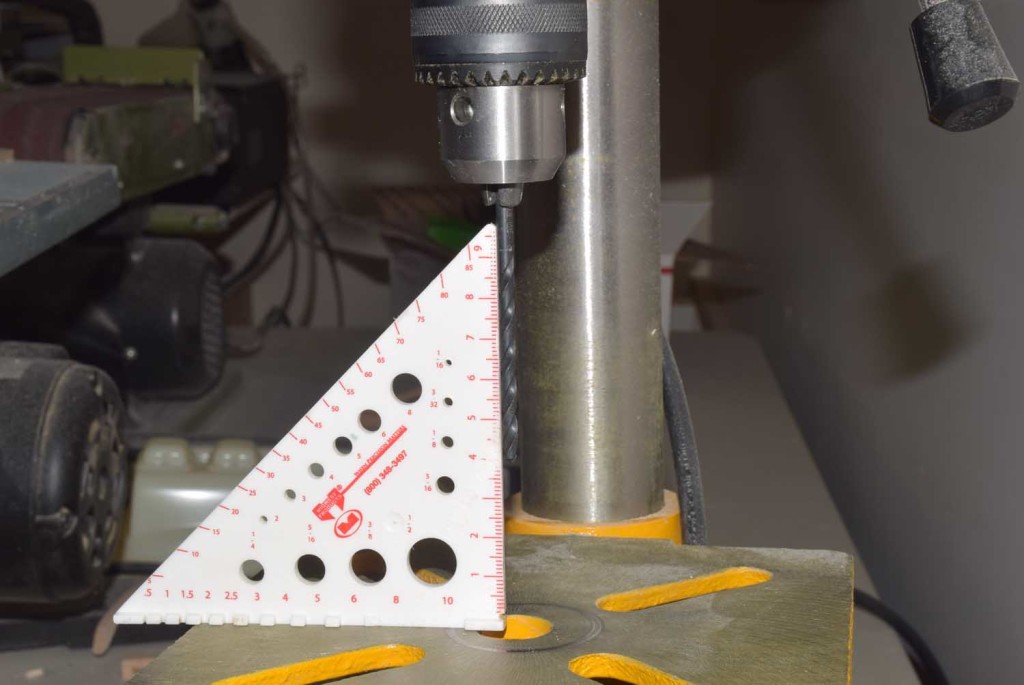

Next we want to make sure the drill press with the #22 bit installed is perfectly square to our drilling surface. Take your time here to get it as perfect as you can.

Next, insert the drill guide into the propeller and drill the first hole. Hold the prop and drill guide firmly on the drill press and slowly begin drilling the first hole. Once the first whole is drilled, insert one of the included bolts to keep the drill guide in it’s place.

Photo below shows the first whole drilled.

Continue to drill the rest of the holes easing the bit down through the guide for an accurate and clean fit!

Final result!

If you have drilled the holes properly, it should be a slightly tight fit when installing the propeller on your engine. This is a good thing and ensures you have an accurately drilled propeller for your DLE engine!